Place a red and white warning tag on the steering wheel.

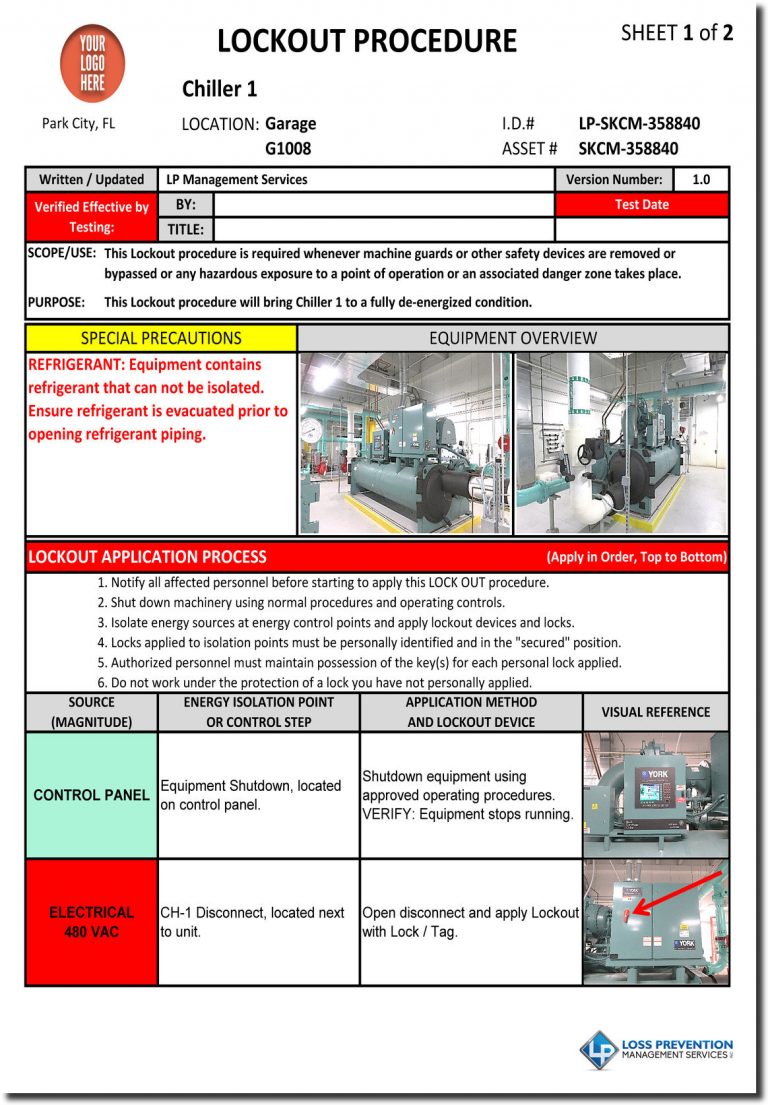

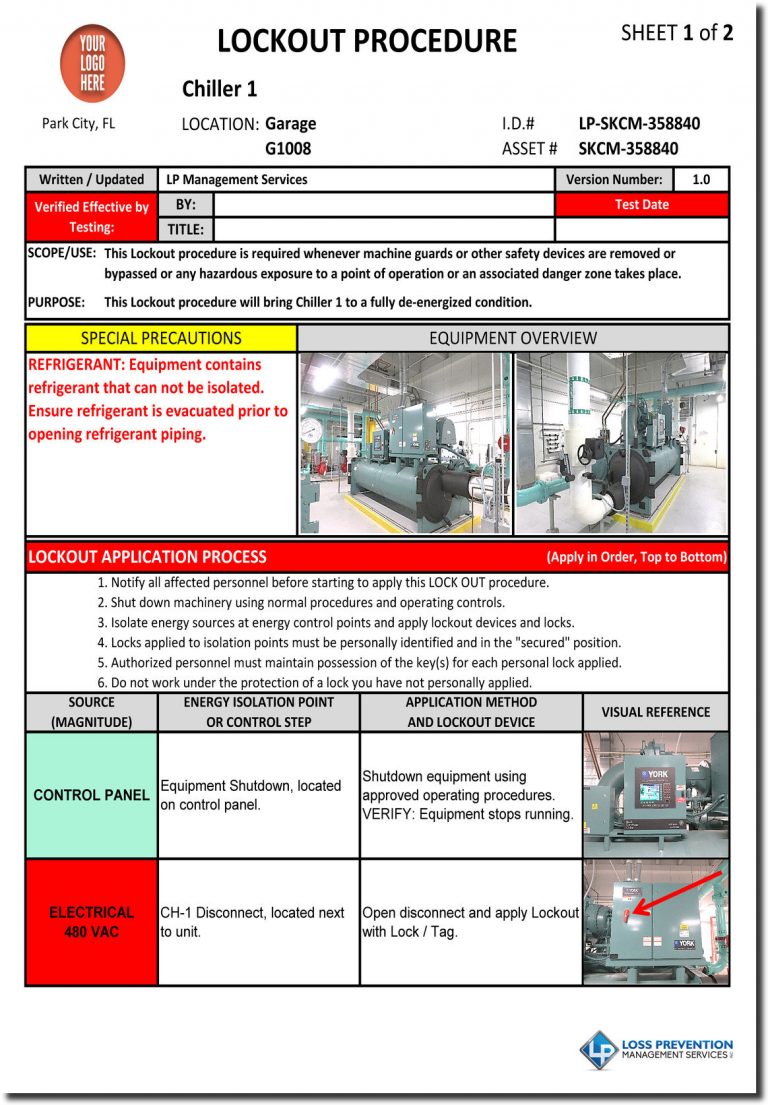

Isolate the lift truck from its energy source(s).

FORKLIFT LOCK OUT TAG OUT INSTALL

Install a locking device approved for the particular forklift to ensure it can’t be powered on.Identify and isolate the forklift to be locked out and tagged out.

Provide training to all employees with proper LOTO procedures so they familiarize themselves with the procedure. That said, this section will give you an idea of some common activities involved in forklift lockout/tagout procedures: Every operation must develop their own guidelines that suit their particular equipment, workflows, and so on. There’s no one-size-fits-all forklift lockout/tagout procedure. This includes group lockout situations when the forklift equipment must be tested or repositioned, when outside contractors work at the site, and during personnel/shift changes. Comply with all other additional energy control provisions in the OSHA standards. Provide effective LOTO training as mandated for all workers, who are involved in LOTO as covered by the standard. Inspect energy control procedures at least annually. Develop a lockout/tagout policy that authorizes the removal of devices solely by the worker who installed them, to maintain control over the equipment. Lockout/tagout application and removal policy. Ensure that lockout/tagout devices identify the individual users. Only use lockout/tagout devices that are approved for the equipment in question, and that meet the requirements of being durable, standardized, and robust. Forklift-authorized lockout/tagout devices. Create, document, implement, and enforce effective energy control procedures Develop, implement, and enforce a clear tagout program if forklifts/ equipment cannot be locked out. Ensure that new or overhauled equipment can be locked out. Tagout devices should only be used in conjunction with lockout devices if the tagout program offers the same level of worker protection as a lockout program. Use lockout devices for forklifts (one that can be locked out). Develop, implement, and enforce an energy control program, employee training, and periodic inspections to ensure that before any servicing or maintenance on a forklift or equipment, it’s rendered inoperative. 147 establishes the minimum performance requirements employers must do to control such hazardous energy. These procedures are designed to protect workers from the startup of the machine or sudden release of energy during servicing and maintenance.

Provide training to all employees with proper LOTO procedures so they familiarize themselves with the procedure. That said, this section will give you an idea of some common activities involved in forklift lockout/tagout procedures: Every operation must develop their own guidelines that suit their particular equipment, workflows, and so on. There’s no one-size-fits-all forklift lockout/tagout procedure. This includes group lockout situations when the forklift equipment must be tested or repositioned, when outside contractors work at the site, and during personnel/shift changes. Comply with all other additional energy control provisions in the OSHA standards. Provide effective LOTO training as mandated for all workers, who are involved in LOTO as covered by the standard. Inspect energy control procedures at least annually. Develop a lockout/tagout policy that authorizes the removal of devices solely by the worker who installed them, to maintain control over the equipment. Lockout/tagout application and removal policy. Ensure that lockout/tagout devices identify the individual users. Only use lockout/tagout devices that are approved for the equipment in question, and that meet the requirements of being durable, standardized, and robust. Forklift-authorized lockout/tagout devices. Create, document, implement, and enforce effective energy control procedures Develop, implement, and enforce a clear tagout program if forklifts/ equipment cannot be locked out. Ensure that new or overhauled equipment can be locked out. Tagout devices should only be used in conjunction with lockout devices if the tagout program offers the same level of worker protection as a lockout program. Use lockout devices for forklifts (one that can be locked out). Develop, implement, and enforce an energy control program, employee training, and periodic inspections to ensure that before any servicing or maintenance on a forklift or equipment, it’s rendered inoperative. 147 establishes the minimum performance requirements employers must do to control such hazardous energy. These procedures are designed to protect workers from the startup of the machine or sudden release of energy during servicing and maintenance.

0 kommentar(er)

0 kommentar(er)